Mepco Label Systems, a manufacturer of pressure sensitive labels and flexible packaging, has added shrink sleeve production to its portfolio. Mepco will be one of a few companies in California to print and seam shrink sleeves. “This will offer our customers the quickest turnaround in the industry and smaller production minimums.,” the company says.

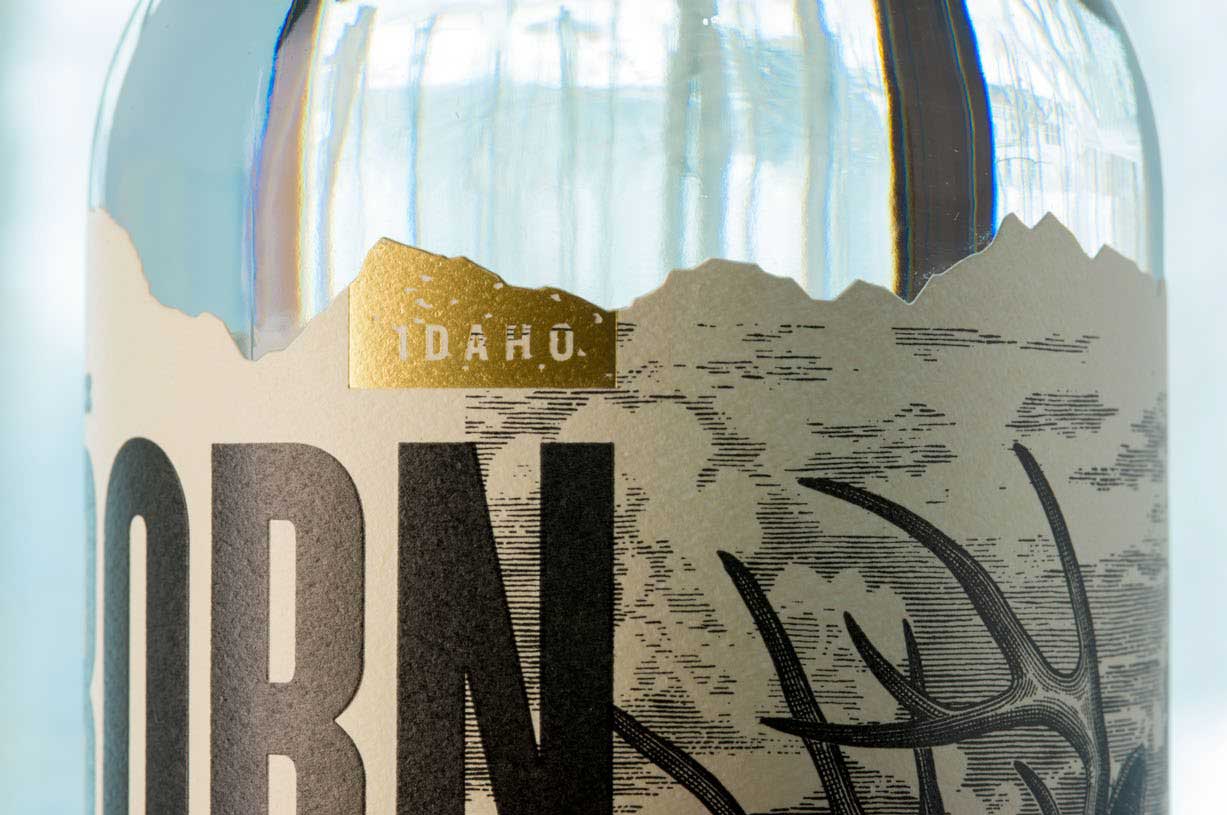

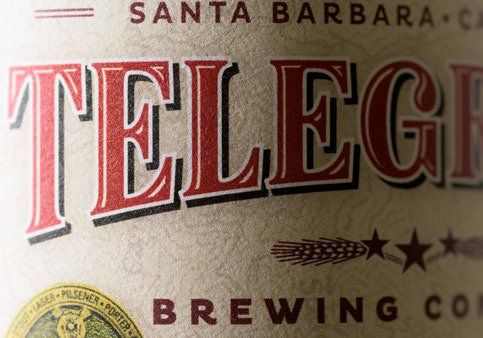

“Offering shrink sleeves to our customers gives our clients a great way to increase the wow factor in product marketing because shrink sleeves offer 360 degrees of print. Shrink sleeves are what consumers are demanding in packaging,” says Jennifer Tracy, president of Mepco Label Systems.

Tracy adds that shrink sleeves are designed to give customers a cost-effective package with freedom of bottle shape, while also providing the most branding area thanks to 360 degrees of print. Shrink sleeves also promote food safety by the ability to combine tamper evidence with the printed sleeve. Mepco will be offering shrink sleeves in PETG, PVC, and PLA.

SHARE POST:

SEARCH POST:

RECENT POSTS: