Thinner, Pressure-Sensitive Film Benefits Label Profile: When a product such as Eternal Water is marketed as pure and pristine, finding a label that reflects these attributes is paramount. In the competitive retail landscape of bottled water, standing out on the shelf is essential to success, and catching the consumer’s eye takes innovation and a bold brand image.

Using naturally alkaline spring water from a protected underground source that is filtered through layers of volcanic rock and sandstone to a vast aquifer providing a natural barrier from any environmental pollutants, Eternal Water is known for its pure product. The natural alkaline properties come from the filtration process in which the water naturally absorbs essential minerals such as calcium, magnesium and potassium. Through pressurization, these naturally occurring minerals in the rock infuse into the water making it alkaline. The location of the springs is carefully selected by the company to ensure its isolation from commercial and industrial pollution.

As sustainability continues to be on the forefront not only for natural water sources but also for bottle-to-bottle recycling, Eternal Water decided to switch to a thinner pressure-sensitive label to help lessen the environmental impact and also benefit the label’s graphic profile.

“The thinner gauge material allows for more labels per roll and increases production,” said Joyce Vagnozzi, regional manager, Avery Dennison Label and Packaging Materials. “Pressure-sensitive film is also a great solution to deliver high-end graphics and with its ability for a one-step process, it can achieve some of the

highest application speeds.”

Previously, Eternal Water used a competitor’s material manufactured outside the United States. They turned to label printer and converter Mepco Label Systems Inc., who then consulted with Avery Dennison. The decision was made to switch

to a Fasson® 1.6 mil metalized BOPP, providing mirror-like refl ectivity, and a 1.6 mil clear BOPP that provides the exceptional clarity needed for this application. The prior labels featured 2 mil BOPP for each material.

Fasson pressure-sensitive has a clear advantage over traditional materials. They provide more brand building and creative freedom, while blending attractively with the substrate, to enhance product image and raise consumer awareness and ultimately, boosting sales.

“Avery Dennison is always great to work with, they have a great customer service and sales team.”

Jennifer Tracy, President, Mepeco Label Systems Inc.

Combined with the brand building capabilities of high-end graphics, self-adhesive is also cost-effective due to a host of operational efficiencies that factor into the production equation for end users. They allow for shorter production runs, faster labeling changes, cleaner processing and better graphic quality results.

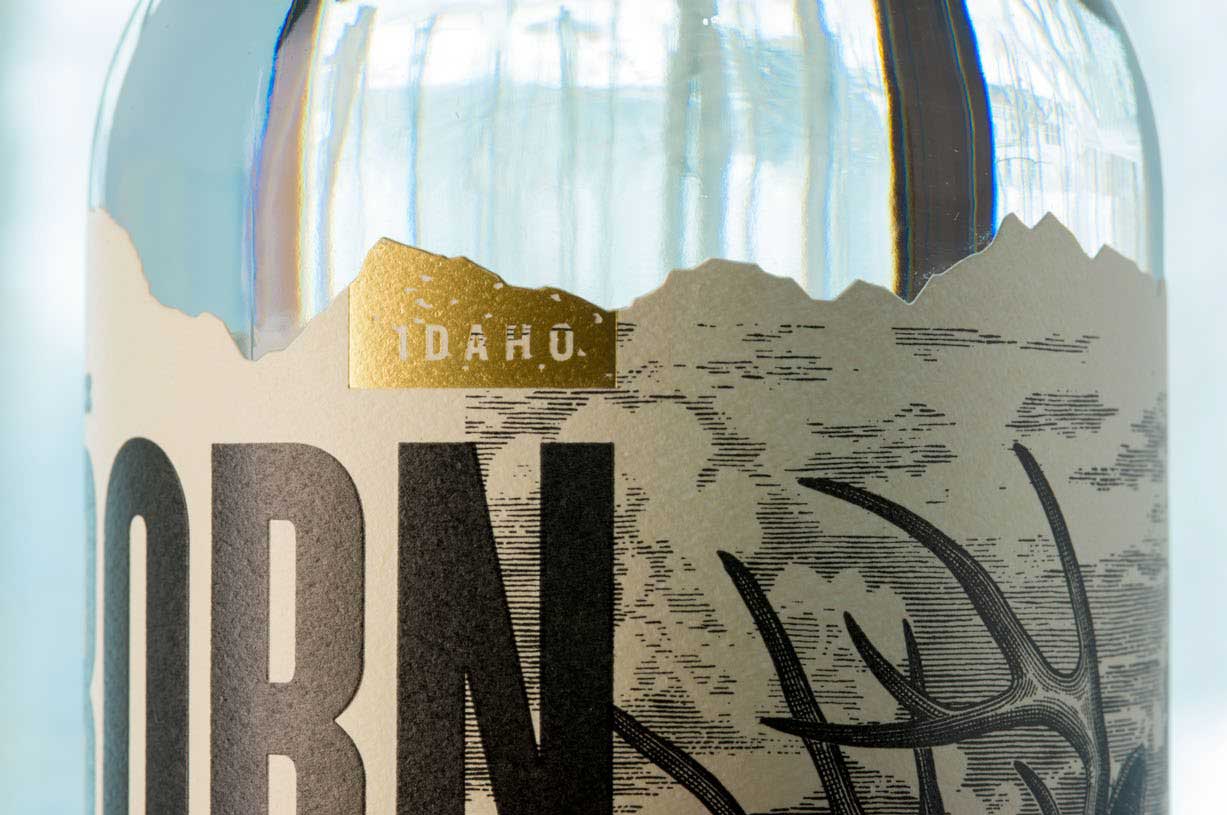

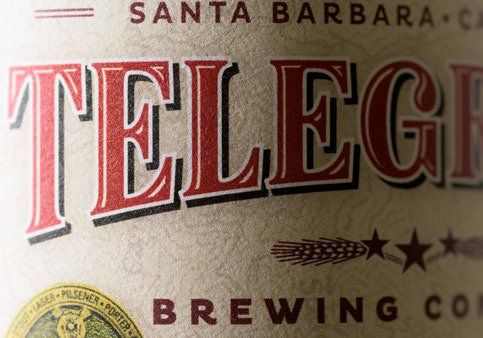

Other benefits of pressure-sensitive labeling besides lower cost is its application is less complex to apply and, with a variety of print processes available, it offers almost endless options for package decoration. Switching to pressure-sensitive can also provide improved operational benefits and efficiencies with more uptime and increased productivity along with reduced scrap. When it came time to produce the labels, Eternal Water again turned to Mepco Label Systems Inc., who specializes in digital and custom labels as well as flexible packaging and promotional labels. The company stepped up to the challenge of producing and printing the nine-color label with the first three colors being reverse printed on clear using a 14-color Mark Andy 2200 press with dual unwinds. The labels were printed HD flexo with both water-based and UV inks at the company’s Stockton, Calif., facility. “We also had the challenge of matching a product that was previously being printed out of the country in New Zealand with other methods of production,” said Jennifer Tracy, president of Mepco Label Systems. “A very fine screen was applied, that went from 98 percent to 2 percent. Anytime you laminate multiple webs you have to make sure your lamination is adhering well and keep the alignment perfect or you can run into problems further down the web when you are printing.” Modifications were also made to the press in house and Mepco Label Systems added a rewinder for the liner from the second unwind, which allows the use of dual pressure-sensitive webs while removing and rewinding the liner on one web. “The brand owner has been very happy with the look of their product,” Tracy said. “They had a look that they were trying to achieve and when shifting the label production from New Zealand to the United States, it was important to maintain the brand look and make it better.”

Design elements ‘pop’at shelf

With the no-label look capability offered by pressure-sensitive, the Eternal Naturally Alkaline Spring Water label has a very organic look featuring the company’s logo predominately at the top. The bottle has a curved design allowing the crisp-plush fern graphic, shown in tones of cool blue, to wrap around the sides and comes in three sizes; 50.7, 33.8 and 20.2 ounces. Key benefits of the water include 8.0-ph naturally alkaline, improved cellular absorption and hydration, naturally occurring electrolytes, BPA free and uses a 100 percent recyclable biobottle. “Because of pressure-sensitive’s ability to be flexible, it is ideal to use on any container type,” Vagnozzi said. “The labels offer high-level print quality, which helps communicate a premium beverage positioning.” The pressure-sensitive labels hit the shelves in early 2012. “Avery Dennison is always great to work with, they have a great customer service and sales team,” Tracy said. “There is always alternative materials and everyone working with Avery has always been willing to jump in to find a solution to any problem that may arise no matter what the application.

© 2012 Avery Dennison Corporation. All rights reserved.

SHARE POST:

SEARCH POST:

RECENT POSTS: