Mepco Label Systems, Inc. is a family-run shop through and through. Led by Jennifer Gassner-Tracy, her parents, Fred and Carol Gassner founded the northern California-based label converter in 1963. Phil Tracy, Jennifer’s husband, oversees the company’s operations, and her brother, Karl Gassner, is head of sales. Mepco employs approximately 106 people operating around the clock.

Challenge:

We had one customer come to us because they had a presentation for Wal-Mart the next day, and they needed 70 labels. We can offer that kind of service, cost-effectively, with the Jetrion.”

Jennifer Gassner-Tracy, President

Jennifer Gassner-Tracy was given the reins of Mepco Label Systems, Inc. two years ago. Once the company invested in digital label production with the purchase of the EFI Jetrion 4000 UV Inkjet System, the Mepco team was able to open its doors to new, higher-end customers, effectively shifting the business from low-cost label producer to highest-value label maker.

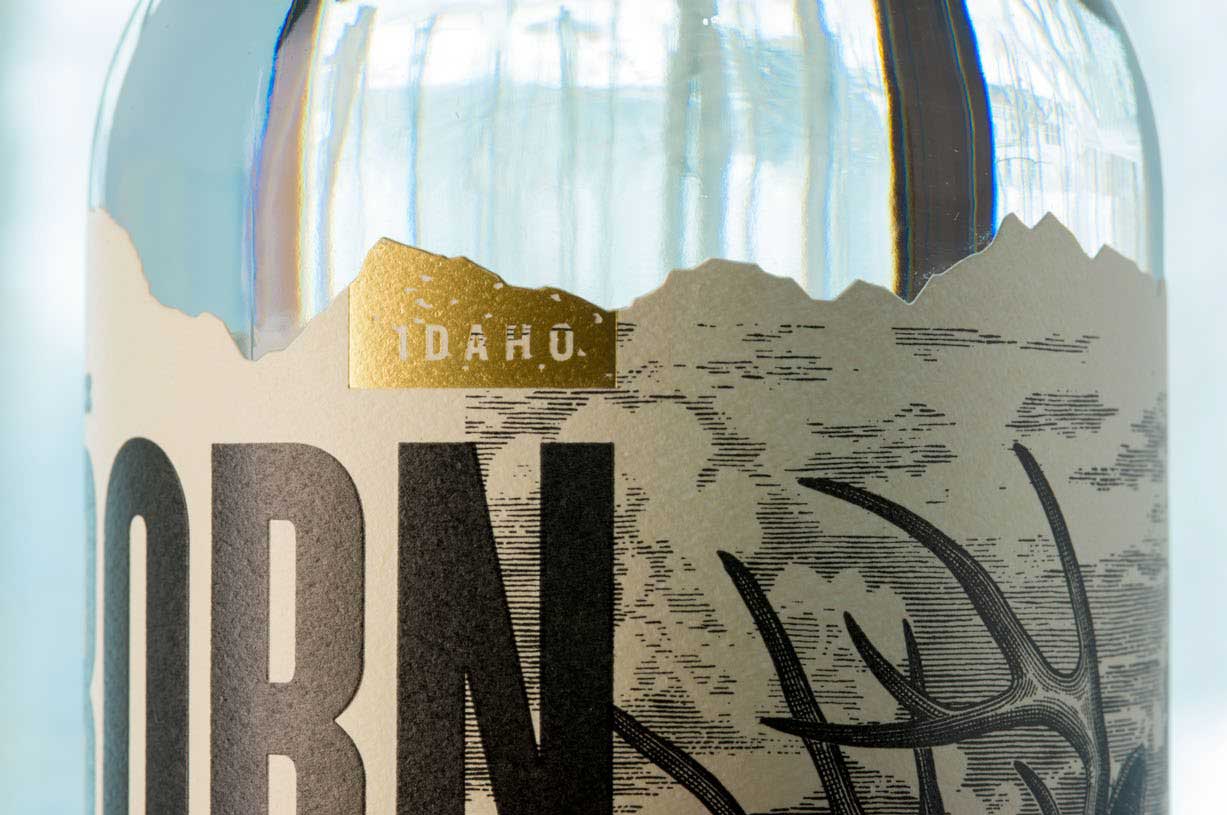

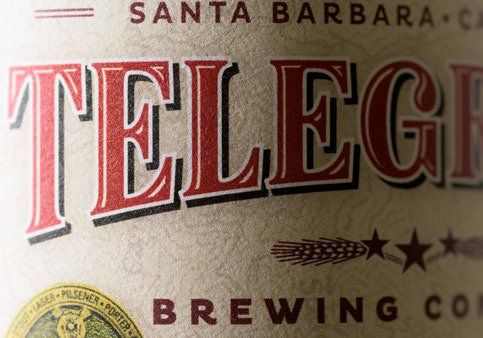

By 2005, the business landscape in the area had started to shift in what seems like contradictory directions. Big-box discount retailers sprouted up along area highways. At the same time, consumer tastes were evolving and demand for locally made luxury products like olive oils, honeys, wines and organic produce began to grow. In the past, Mepco ran profitably in a very basic label business, printing a lot of dairy and meat labels. “Certainly, quality was important, but there’s a big difference between the three-color milk labels and higher-end labels we do today,” says Jennifer Gassner-Tracy,

president of Mepco Label Systems, Inc.

Two very different consumer trends – one toward mass-market buying and the other toward high-end, locally branded products – meant the same thing for Mepco’s business: growth in demand for short-run label jobs. Suppliers to the big-box retailers were beginning to ask for rapid turnaround test products and seasonal promotions, and the local brands needed fewer, higher-end labels for their unique product lines. These jobs were too expensive to run on Mepco’s existing flexo equipment, because set-up times for multiple jobs, scrap and test runs ate away at profits. Mepco first began exploring digital options at Labelexpo in 2008 with the digital printing innovator, EFI, and the company’s Jetrion 4000.

Solution:

“We were weighing inkjet and toner-based options,” says Phil Tracy, Vice President of operations for Mepco “but when we looked at ease-of-use, simplicity of pricing, and most important, print quality, the Jetrion 4000 UV Inkjet System was the obvious choice.”

Mepco already printed with UV ink, and they wanted to be able to print with materials they used every day. They liked the durability of the inks, and the cost-savings gained in not having to coat paper after printing. A key consideration was also the environmental benefit of UV inkjet inks, which are non-VOC, a particularly important attribute in California where the regulatory environment is the toughest in the United States.

Tracy also had experience with EFI’s Fiery® XF color management system. That same software powers the color match and color-proofing systems in all Jetrion units, and so, he says they knew the quality they were buying into. A few months later, they made the purchase. EFI Jetrion also offers a full-service training program to get people up to speed quickly on how to use the press. “We were concerned about the transition initially, but it was very smooth,” adds Tracy. “We have one operator who runs the digital press, and it’s very easy.”

Results

Gassner-Tracy saw the opportunity to build new business with the Jetrion system. “We’re going into specialty foods, like pastas, organic honeys, and all-natural makeup and soap, and smaller wineries, too. Napa is right next door, and we have an opportunity to do a lot for quality-focused Mom and Pop vintners in the area,” she says. “The Jetrion’s UV Inkjet printing makes it ideal for labels for consumer uses, because the ink is durable and can withstand bathroom moisture, kitchen oils and even the cold temperatures of freezers. Products look beautiful in the store and in the home, use after use.”

“The Jetrion is running 10 hours a day, 5 days a week. It’s much more cost-effective for our customers, because they don’t have to invest in plates and expensive set-up runs with this system.”

Phil Tracy

Vice President of Operations

Mepco Label Systems, Inc

The company also saw the incredible advantage of being able to offer fast-turn around service for suppliers of retailers like Wal-Mart and Sam’s Club. “We operate in emergency mode for many of our customers,” says Jennifer. “We had one customer come to us because they had a presentation for Wal-Mart the next day, and they needed 70 labels. We can offer that kind of service, cost-effectively, with the Jetrion.”

With fourteen presses, the company continues to support a sizable flexo business; and the customer base has significantly broadened because of the Jetrion 4000. Mepco now offers labels for product runs of anywhere from 1,000 to 50,000 plus. The Jetrion is running 10 hours a day, 5 days a week. “It’s a much more cost-effective choice for our customers, because they don’t have to invest in plates and expensive set-up runs with this system,” says Phil.

There’s no denying Fred Gassner’s touch remains firm on the business. “My father taught me to stand by what we make, do everything we can to help our customers and make sure we’re on top of our game,” says Jennifer. “Thanks to the EFI Jetrion, we have been able to embrace higher-end customers and support customers the way my father taught us to. It’s been hands down great for our business.”

Beat the competition and profit with EFI’s integrated Fiery®, VUTEk®, Jetrion®, Rastek™, Print MIS and Web-to-Print solutions. Visit www.efi.com to learn more.Print to Win™ with EFI™ (www.efi.com).

SHARE POST:

SEARCH POST:

RECENT POSTS: